Mechanical assemblies demand more than just holding parts together. The choice between different joining methods affects how accurately components align, how well they resist movement, and how consistently they perform over time. Engineers face this decision regularly, particularly in applications where position matters as much as strength.

Understanding the Fundamental Difference

- Force vs Position: Bolts and screws from best fasteners manufacturers in India generate clamping force that holds components together through friction and compression. They excel at resisting separation and handling dynamic loads. The threaded design allows controlled tension, making them ideal for joints that need specific preload values or occasional disassembly.

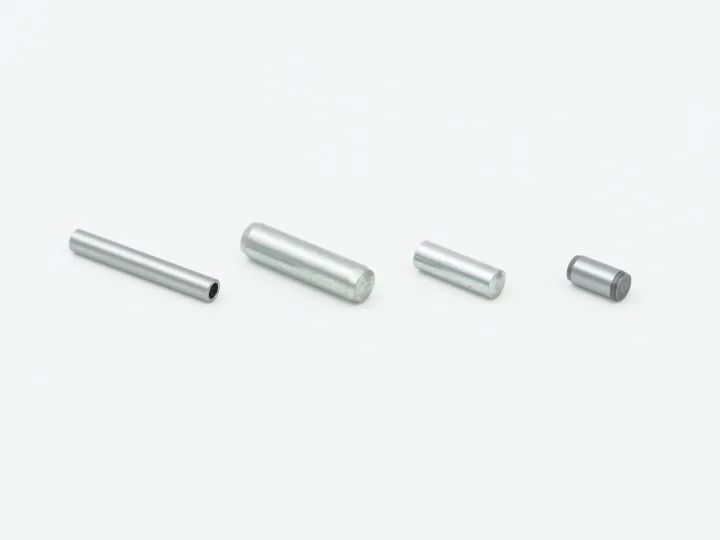

- Precision Placement: Dowel pins operate on a different principle altogether. These cylindrical components fit into precisely reamed holes, creating a mechanical interlock that prevents lateral movement. Their interference fit establishes a fixed reference point between mating parts. This becomes critical when components must return to exact positions after maintenance or when assembly tolerances cannot exceed a few hundredths of a millimetre.

When Dowel Pins Become Essential

- Mould and Die Applications: Tool and die assemblies require absolute repeatability. When mould halves separate for part ejection and close thousands of times, any misalignment compounds into defects. Dowel pins ensure the cavities meet at identical positions every cycle, maintaining tight tolerances on finished parts.

- Heavy Machinery Alignment: Large equipment frames and housings often combine both solutions. Fasteners carry the structural loads, pins handle the positioning. This division of labour prevents bolt holes from elongating under vibration and shifting loads. The pins absorb shear forces that would otherwise work against the bolt threads.

Load Direction Determines the Right Choice

- Shear Strength Considerations: Pins typically offer superior shear resistance compared to threaded fasteners of similar diameter. The continuous cylinder distributes forces evenly across its length. Bolts concentrate stress at thread roots, making them more vulnerable to lateral loads. Applications with significant side forces benefit from pin reinforcement.

- Tensile Requirements: Fasteners dominate when pull-apart forces exist. Their threads convert rotational torque into axial clamping force. Pins cannot generate this type of holding power. They rely on friction from their press fit, which may loosen under sustained tensile loading or thermal cycling.

Design Considerations for Combined Systems

- Hole Preparation Matters: Achieving proper pin function requires reamed holes with specific tolerances. Standard drilled holes lack the accuracy and surface finish needed. This adds manufacturing steps and cost. Fastener holes accept wider tolerances, simplifying production but sacrificing positional precision.

- Assembly Sequence Planning: Engineers must consider how components come together. Pins typically install first, establishing alignment before fasteners apply clamping force. This sequence prevents binding and ensures both elements work as intended. Some designs use slip-fit pins that allow adjustment before final reaming takes place.

Material Selection and Surface Treatments

- Hardness Requirements: Dowel pins need sufficient hardness to resist deformation in their interference fit. Common materials include:

- Ground and hardened steel pins for general industrial use

- Stainless steel variants for corrosive environments

- Carbide pins for extreme wear resistance in production tooling

- Coated options for specific friction or galvanic compatibility needs

- Corrosion Protection: Both joining methods require appropriate surface treatments based on operating conditions. Zinc plating suits mild environments, specialised coatings handle chemical exposure or extreme temperatures. Material compatibility between pins, fasteners, and joined components prevents galvanic corrosion.

Maintenance and Serviceability Factors

- Disassembly Frequency: Joints needing regular access favour fasteners alone. Removing press-fit pins risks hole damage, particularly in softer materials like aluminium. Some designs use slip-fit or shoulder pins that extract easily, trading some precision for serviceability. The application determines acceptable compromises.

- Wear Patterns: Pins in high-cycle applications eventually develop wear from micro-movements. Regular inspection catches elongated holes before alignment suffers. Replacement schedules based on cycle counts prevent unexpected failures. Fastener joints may require periodic retorquing as embedment relaxation occurs.

Selecting between dowel pins and fasteners comes down to their primary function. Pins deliver positional accuracy and shear resistance. Fasteners provide tensile strength and adjustable clamping force. Many critical assemblies use both, leveraging each component’s strengths. Evaluate your alignment tolerances, load directions, and maintenance requirements. The right combination ensures reliable performance and extends service life. Consider consulting experienced suppliers who understand both positioning and fastening solutions for optimal results.

Featured Image Source: https://sp-ao.shortpixel.ai/client/to_auto,q_glossy,ret_img/https://upsind.com/wp-content/uploads/2024/05/Dowel-pin-2-1.png